Your Cart is Empty

Solid Ash pedestal expanding table with Wenge pin striping detail

June 29, 2022 5 min read

Solid Ash pedestal expanding table with Wenge pin striping detail.

Having been contacted by very discerning clients we were honoured to accept he commission to design, make, and install a dining table of some note.

It was to be installed in the client’s private river side residence as part of a fundamental and complete property remodelling project.

The overall project went to the lengths of installing the latest environmentally energy supply technologies. Ground source heat pumps, river bases, solar etc...

Our part of this bigger project was to develop the refined design working with the clients to create something truly magnificent and grand and in keeping with the wonderfully bold palettes of the clients’ taste. Was to bring the soft and tactile elements which well-made natural hardwood pieces do yet retain a modern twist linking other elements in the dining / kitchen space. The table was to be front and centre in the space and is to be used daily. Because of the daily use by the clients who also frequently entertain family and friends the table was also to be fully expanding.

The dimensions were specific. 1.3m diameter round table, which expands to an elongated circle some 2.8m length.

Other elements of the brief were respects the ash itself and that the boards used for the table top were to be grain matched when the table is in its round or closed format as this is the most common format for the table on a daily basis.

Client meetings were had regards the design, and then also the material selection. The clients were clear very early on that our own harvested, milled and dried English Ash was the material for choice.

With the design and material choices agreed, it was now up to us to create and turn this into a physical reality.

With such a geometric design the importance on the correct joints and construction techniques was paramount.

To get the Ash to the correct moisture content and stability was equally important.

I proposed making a half scale model of just the tabletop to test the joints and moisture elements. My suggestion was that the half-sized model if acceptable to the clients could be repurposed as a Lazy Susan and add to the collection. I noted a fantastic, curved marble breakfast bar area in the open plan dining space, and could see this being of some use here.

They loved this idea and we proceeded.

Follows is a pictorial process of the kiln drying and manufacturing process of the 1/2 sized model and also then full-sized table at our workshops then with some shots of the installation at the clients home.

Thank you for taking the time to read and see the pictures. If there is any enquiries for any design, build and install projects you have in mind, then please do get in touch.

Pete, Jen, Olivia and Herbert.

01452741298

info@thefinewoodenarticleco.com

Half Sized Table Top.

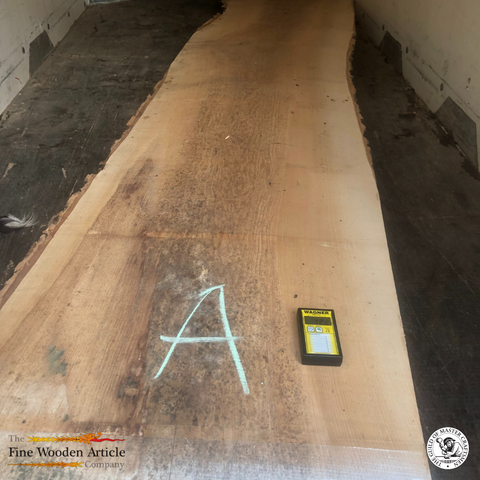

Stock going in the kiln at circa 15% moisture.

The beginnings of the pedestal assembly.

The pedestal's edge angles were critical.

Early stage, mocked up tip testing with the team.

Lets increase the load!

And some more!! Its exceeding the calculations by some considerable margin. Great stuff!

Gluing up the pedestal base on the formers and adding the Wenge pinstripe detailing strips. All will be revealed!

Interesting angle.

Primary clean up of the base parts.

Moving onto the slabs to make the top from. These are edge bonded and mortice tendon jointed.

Surfacing on the CNC.

Components cut to shape and offered up to mark out the joints and detailing.

The 2 hemispheres forming the circular configuration, all jointed and glued up.

Joints and accuracy for this was critical. Mortice, tennoned and pegged. Its all there!

The removable leaves being assembled.

The first time seeing the table as a whole together.

Love the contrasting detail of the pin striping.

Starts to take shape.

Details.

Coming together.

Lets look at the siding mechanism. Custom made in Italy.

The bases and structure to join the top in conjunction with the slider.

Wenge detailing flowing through to the internal faces of the pedestals.

Steam bending the skirt.

Skirt being fitted.

Pre finishing.

That slider!

Getting there.

Yep. Getting there.

WOW.

The clients new kitchen. I love it.

Brave, but it works, so well.

Amazing.

Stunning space.

The half sized test piece at the begging the project becomes a lazy suzan for the centre of the table or the counter top.

Below is copy and paste of an e mail review from our client.

Hi Peter

Apologies for the delay in responding fully to this and hope all is well with the family and you.

Below my version, anna may want to add some of her own flavour to it

Converting an idea into a beautifully crafted functional dining table that is now the centrepiece of our Kitchen.

When we started this journey, and that is what it has been, we knew we wanted a round table that could seat 4/5 people easily for everyday use but be able to extend to accommodate 10/12 people when we entertain. It had to fit in with a very modern kitchen and be an attractive piece of furniture in its own right but also be something special. This is what we had in heads when we talked with Peter who quite rightly wanted to ensure that we were not just commissioning a piece of furniture but looking at something that would last a lifetime and also give joy. Peter then showed us his treasure of timber and each one had its own history, we choose an ash as we wanted a light colour and were taken with how this wood had been salvaged from a tree that had to be cut down due the disease.

Peter researched through how the very technical and mechanical elements of this project could work as well as how the timber would need to be treated to cope with the stresses and temperature variations. This took time to work through and Peter very kindly shared his thoughts at every stage and patiently worked through our suggestions as well as the technical skill required to produce the finished product.

It has taken time for our idea to become reality and we now have a dinning table that we love. It looks and feels beautiful, I find myself sometimes just sitting there and just feeling the wood! The end product has drawn a lot of appreciative comments from friends, and we love having it in our kitchen. I personally feel that I am just the current custodian of something that future generations will also enjoy.

I am really grateful to Peter for his technical knowledge to bring this to life and we share his joy in enjoying the table.

Hope this is ok and once again apologies for the delay. Just to add we are really enjoying the table

Regards

Janardan

Pete, Jen, Olivia and Herbert.

01452741298

info@thefinewoodenarticleco.com

Leave a comment

Comments will be approved before showing up.

Also in News

The Perfect Touch for Country Venues – Oak Framed Tree Swings

November 07, 2024 1 min read

For country hotels, spa retreats, and wedding venues, creating a warm, inviting atmosphere is everything. Our Oak Framed English Oak Tree Swings offer just that—a timeless addition that’s as delightful to look at as it is to enjoy.

6.5m Long Conference Table.

April 01, 2022 3 min read

Through all of the meetings concluding these material decisions the brief had one word resonating and presiding over all. "WOW." The table had to have WOW factor.

Recent Articles

- The Perfect Touch for Country Venues – Oak Framed Tree Swings November 07, 2024

- Solid Ash pedestal expanding table with Wenge pin striping detail June 29, 2022

- 6.5m Long Conference Table. April 01, 2022

- Hairworks, Hair Salon, Whitminster. March 22, 2022

- English Oak, Country Cottage Kitchen Island. February 09, 2022

Categories

- adulttreeswing

- Australian Aboriginal Art

- Bay Gallery Home

- bespoke

- Bookshelf

- Ceramic Tiles

- Collaboration

- commission

- designer maker

- English heritage

- Engrave

- Garden

- Glass

- Gloucestershire

- MDF

- Oak

- Personalise

- Pippy Oak

- press

- Room Divider

- shipwright

- solid oak pergola

- sustainable

- Swing Seat

- Table

- The Stroud News

- treeswing

- wood

- woodcraft

- workshop

- youarenevertooold

Sidebar Content

You can add a content block like this to your blog article sidebar, and use it for more details about blog authors, for example.

Subscribe

Sign up to get the latest on sales, new releases and more …